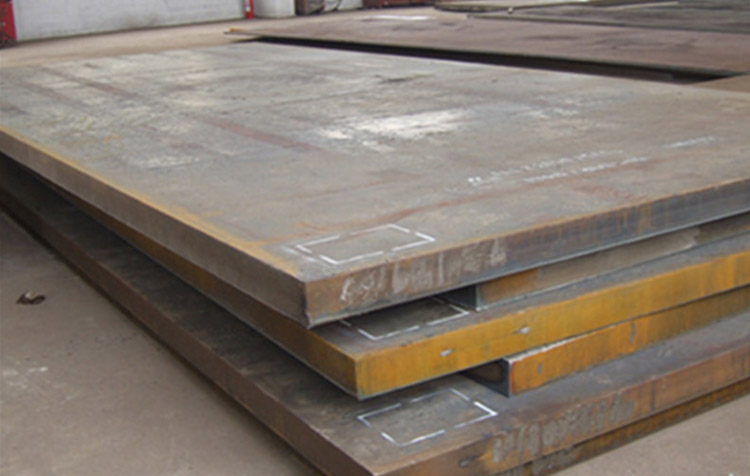

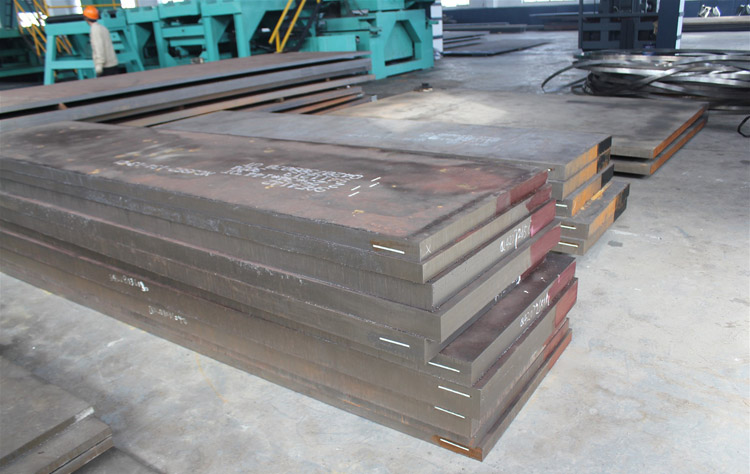

NM450 wear resistant steel

Chemical Composition (%) of NM450 Wear Resistant Steel

|

C |

Si |

Mn |

P |

S |

Al |

Cr+Mo+Ni |

|

0.10-0.40 |

0.20-0.40 |

1.0-2.0 |

≤0.015 |

≤0.003 |

≥0.02 |

<1.2 |

Mechanical Properties of NM450 Wear Resistant Steel

|

Thickness/mm |

ReL /MPa |

Rm /MPa |

A/% |

Hardness/ HBW10/3000 |

Impact -20℃ /J |

|

8 |

1250 |

1460 |

16 |

445 |

40 |

|

12 |

1290 |

1470 |

17 |

462 |

43 |

|

20 |

1370 |

1450 |

17 |

473 |

42 |

|

25 |

1230 |

1480 |

16.5 |

465 |

43 |

Wear-resistant steel NM450 is a high wear-resistant high-end varieties, with good cutting, bending, welding performance. Wear-resistant steel (Abrasion Resistance Steel ) is widely used in engineering, mining, construction and agriculture machinery products under extremely harsh working conditions with the requirement of high strength and high wear resistance, such as bulldozers, loaders, excavators, dump trucks and various mining machinery, etc. This kind of product has been mated for well-known domestic engineering machinery factories in mass as an ideal substitute of expensive imported wear-resistant plates.

Get In touch with