steel coil

Steel Coil

- Hot-Rolled Steel Coil: any size coil by request

- Cold-Rolled Steel Coil: any size coil by request

- A36, A283, A514, A572, A573, A588, A633, A656, A709,

- SA36, SA283, SA514, SA572, SA573, SA588, SA633, SA656, SA709

- EN10025-2, EN10025-3, EN10025-4, EN10025-6

- JIS G3101, JIS G3106, DIN 17100, DIN 17102

- GB/T700, GB/T1591, GB/T16270

Anson supplies a wide range of cold-rolled and hot rolled steel coils according to China Industrial Standards, the standards of other countries and our own strict standards.

Cold-rolled steel coils are widely applied to automobiles, electrical appliances, steel office equipment, containers, and numerous other products closely connected to pour daily lives.

Hot-rolled steel coils are applied to wide range of uses such as, automobiles, electrical appliances, construction materials, steel silos, containers and steel pipes, and receive high assessment from our overseas customers for its supreme quality.

Carbon and Low-alloy High-strength Steel Coil

Pipeline Steel Coil

Shipbuilding Steel Coil

Weather Resistant Steel Coil

Hot Rolled Steel Coil for Oil Casing

Hot Rolled Steel Coil for Automobile Frame

Steel Coil for Gas Cylinders and Gas Vessels

We committed to meet our customers’ requirements of quality as well as on-time delivery and offer technical consultations and services for applications of our steel products.

Difference Between Hot Rolled and Cold Rolled Steel Coil

Customers often ask us about the differences between hot rolled coil and cold rolled coil. There are some fundamental differences between these two types of metal. These differences relate to the ways these metals are processed at the mill, and not the product specification or grade.

- Hot rolling is a process at the steel mill which involves rolling steel above its recrystallization temperature, typically over 1700° Fahrenheit.

- Steel that is heated above the recrystallization temperature can be shaped and formed more easily, which allows the steel to be made in much larger sizes.

- Cold rolled steel is more expensive than hot rolled steel in most circumstances. This is because hot rolled steel is manufactured without any delays in the process which require reheating the steel.

- When the steel cools off it will shrink slightly thus giving less control on the size and shape of the finished product when compared to cold rolled.

- Cold rolled steel is processed further in cold reduction mills, where the material is cooled followed by annealing and/or tempers rolling.

- The cold reduction process will produce steel with closer dimensional tolerances and a wider range of surface finishes.

- The term cold rolled is mistakenly used on all products, when actually the product name refers to the rolling of flat rolled sheet and coil products.

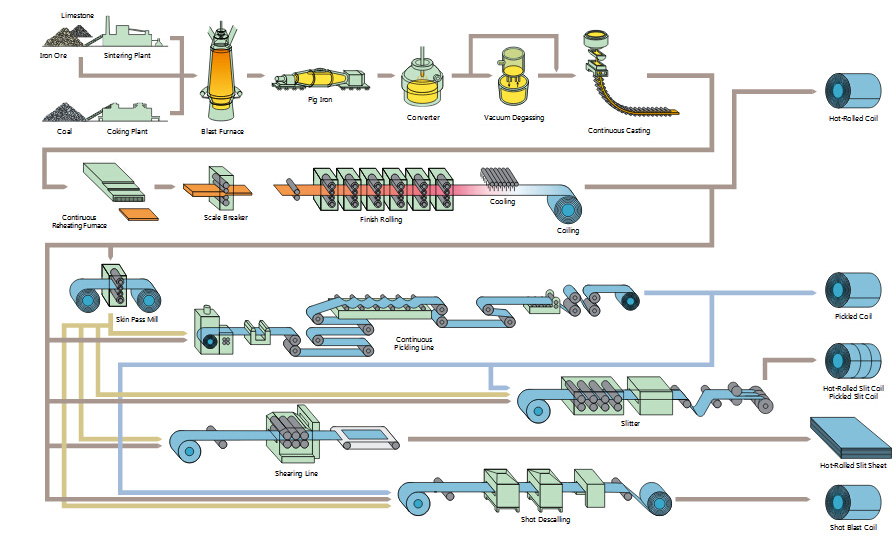

Hot-Rolled Steel Coil Manufacturing Processes

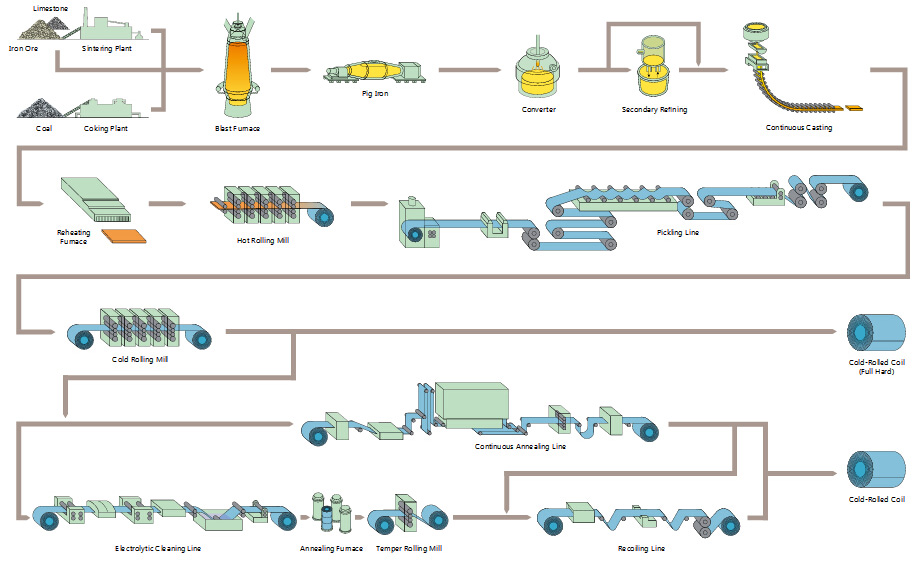

Cold-Rolled Steel Coil Manufacturing Processes

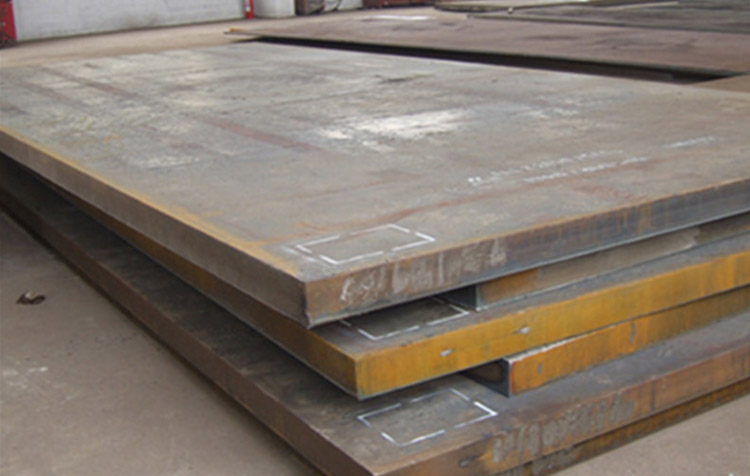

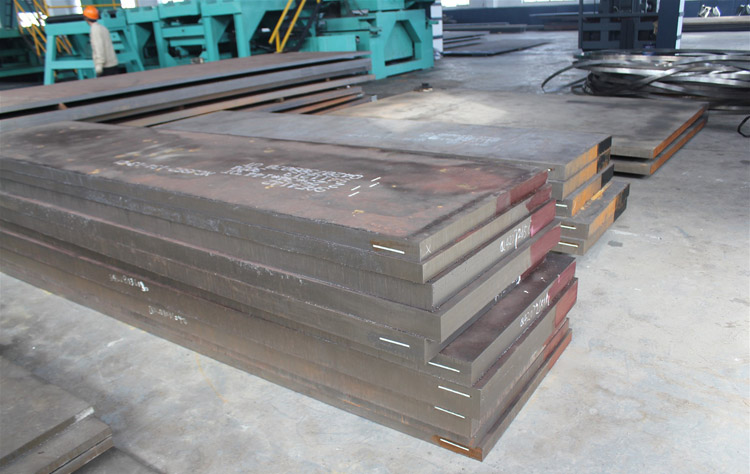

- NM400 steel plate

- low alloy steel plate

- Cor-Ten steel plate

- stainless steel plate

- pipeline steel plate

- pressure vessel steel plate

- abrasion resistant steel plate

- shipbuilding steel plate

- steel coil

- carbon steel plate

- Cold rolled steel coil

- testing

- quality policy Steel Grades

- EN 10130 cold rolled steel coil specification

- GB/T5213 - 2008 cold rolled coil

- JIS G3141 steel coil specification

- NM500 wear resistant steel

- NM450 wear resistant steel