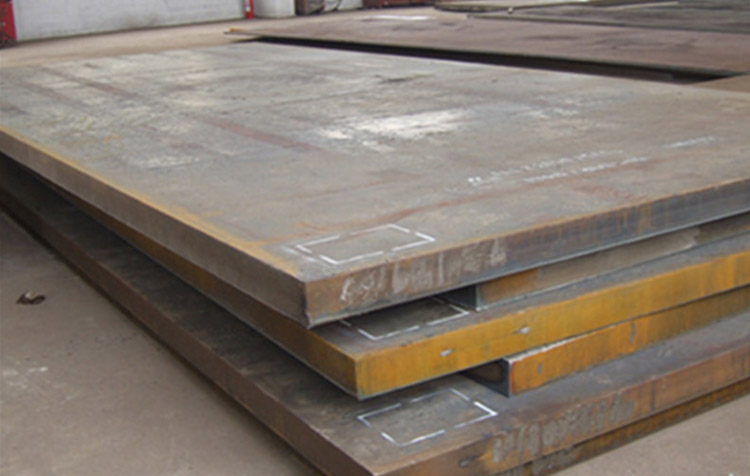

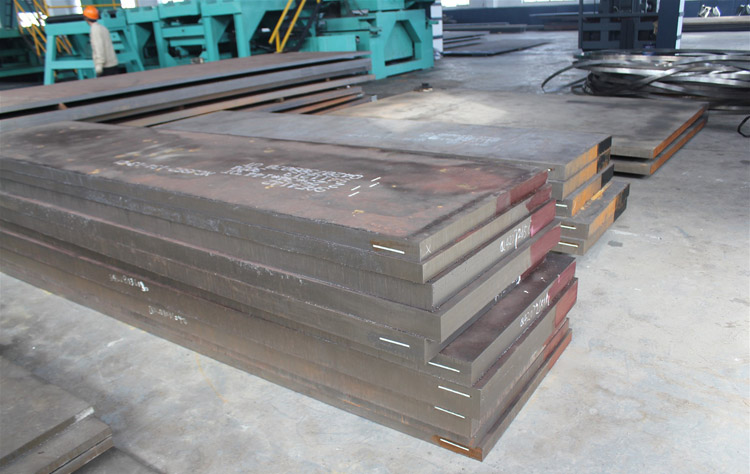

Cor-Ten steel plate

COR-TEN has served as weathering steel (atmospheric corrosion- resistant steel). Corten steel plate has successfully overcome rust, steel’s most weakest. When exposed to the atmosphere without painting, corten steel begins to rust in the same way as ordinary steel. BUT soon the alloying elements in COR-TEN cause a protective surface layer of the fine-textured rust to form, thereby suppressing corrosion rate. Since its development in 1993, the COR-TEN has been used in every field where steel applied, such as bridges, railway vehicle and buildings. At present, COR-TEN are attracting attention as being suited for resources and environmental concerns as well as reducing life-cycle costs.

Features of COR-TEN

- Weathering Resistance

Thanks to high weather resistance, corten steel can be used without painting. Unpainted applications are not only offer the economic advantage of reducing repainting costs; they also offer aesthetic benefits associated with the calming color of the protective rust.

- Paint Durability

COR-TEN is paintable in the same way as ordinary steel. In addition, even if a painting defect should occur, COR-TEN suppresses the progress of rust area and prolongs the services life of paint, thereby reducing repainting costs.

- Weldability

While trace amounts of alloying elements such as copper (Cu) and chromate (Cr) are added to COR-TEN to ensure high weather resistance, the carbon content is lowered to provide appropriate weldability. Accordingly, COR-TEN can be welded using either manual, gas-shield or submerged arc welding.

- Workability

COR-TEN possesses workability similar to ordinary steels of same strength.

- Reliability

Since 1959 when COR-TEN began to be marked, more than 4.8 million tons of this material have been produced. (2015 end)

Unpainted use of Cor-Ten

The unpainted application of corten steel not only offer economic advantages but also demonstrates excellent aesthetic properties. Because of this, COR-TEN is applied in a wide range of fields such as buildings and monuments. COR-TEN can be applied without painting-in a bare state, thus reducing the cost of repainting and other repairs. However, some of our clients have expressed their concerns during the first year or two then the protective lay of fine-textured rust is forming. In order to solve these concerns, supplementary rust stabilization treatment was developed.

Painted use of Cor-Ten

When COR-TEN is painted, the required number of times that repainting must be conducted can be reduced. This advantage is believed to result from the fact that, even when corrosion in the base metal due to defects in the panted film or to pinholes, the corrosion progresses slowly and thus the occurrence of blistering and peeling of the paint film is reduced. By making the most of this advantage. COR-TEN is applied in every field where steel is used-ranging from buildings to railway vehicle, marine containers, storage tanks, industrial machinery and bridges.

| ASTM Corten A Chemical Composition | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Grade | C Max | SI | Mn | S Max | Cr | Ni | Cu | Nb | Nb+V=Ti |

| Corten A | 0.12 | 0.25-0.75 | 0.20-0.50 | 0.07-0.15 | 0.030 | 0.50-1.25 | 0.65 | 0.25-0.55 | - |

| ASTM Corten A Mechanical Properties | |||||

|---|---|---|---|---|---|

| Grade |

Permissible yield point ratio |

Yield Strength MPa(min) |

Tensile Strength MPa |

Elongation % (min) |

Bend |

| Corten A | - | 355 | 470-630 | 20 | 1t |

| Corten A Weathering Steel Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| Recommended Bending Radius without Special Requirments | ||||||||

| Thickness mm | 2-3 | 4 | 5 | 6 | 7 | 8 | 10 | 12 |

| Radius mm | 4 | 8 | 10 | 12 | 21 | 24 | 30 | 36 |

| ASTM Corten B Chemical Composition | ||

|---|---|---|

| Grade/ Material | Element | Composition( Max-A, Min-I) |

| Corten B | C | A: 0.19 |

| Mn | 0.30-0.65 | |

| Si | 0.80-0.25 | |

| P | A:0.035 | |

| S | A:0.030 | |

| Al | 0.020-0.06 | |

| V | 0.02-0.10 | |

| Cu | 0.25-0.40 | |

| Cr | 0.40-0.65 | |

| Ni | 0.40 | |

| ASTM Corten B Mechanical Properties | ||

|---|---|---|

| Grade/Material | Tensile Test | Ksi/MPa |

| Corten B | Tensile Strength | I:485 |

| Yield Strength | I:345 | |

| Elongation | 19% | |

| Impact Test(if any) | ||

- NM400 steel plate

- low alloy steel plate

- Cor-Ten steel plate

- stainless steel plate

- pipeline steel plate

- pressure vessel steel plate

- abrasion resistant steel plate

- shipbuilding steel plate

- steel coil

- carbon steel plate

- Cold rolled steel coil

- testing

- quality policy Steel Grades

- EN 10130 cold rolled steel coil specification

- GB/T5213 - 2008 cold rolled coil

- JIS G3141 steel coil specification

- NM500 wear resistant steel

- NM450 wear resistant steel