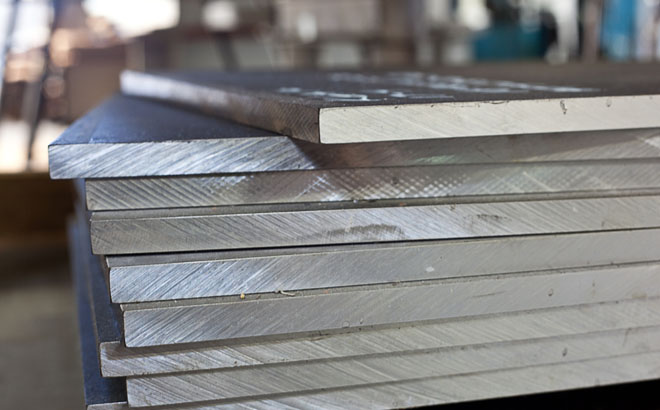

stainless steel plate

Stainless Steel Plate

Standard: 302, 304, 304L, 309, 316, 316L, 317, 321, 330, 403, 409, 416, 440C, Duplex 2507

Sizes: from 3/16" to 2" thick x 48" or 60" wide x 96/120/144 lengths

Chemical composition, mechanical properties, weldability and corrosion resistance provide the best all-round performance stainless steel plate at relatively low cost.

Stainless Steel Plate Stock:

Chemical and Mechanical Properties of Stainless Steel Plate:

| Typical chemical requirements | ||||

|---|---|---|---|---|

| 304 | 304L | 316/316L | 321 | |

| Carbon, Max % | 0.07 | 0.03 | 0.03 | 0.08 |

| Manganese, Max % | 2 | 2 | 2 | 2 |

| Phosphorus, Max % | 0.045 | 0.045 | 0.045 | 0.045 |

| Sulphur, Max % | 0.03 | 0.03 | 0.03 | 0.03 |

| Silicon Max | 0.75 | 0.75 | 0.75 | 0.75 |

| Chromium range | 17.5-19.5 | 17.5-19.5 | 16-18 | 17-19 |

| Nickel range | 8.0-10.5 | 80.-12 | 10-14 | 9-12 |

| Nitrogen Max | 0.1 | 0.1 | 0.1 | 0.1 |

| Mechanical Properties | ||||

| Tensile Min | 75 ksi | 70 ksi | 75 ksi | 75 ksi |

| Yield Min | 30 ksi | 25 ksi | 25 ksi | 30 ksi |

| Elongation Min | 40% | 40% | 40% | 40% |

| Hardness Max | 95 HRB | 95 HRB | 95 HRB | 95 HRB |

Stainless steels are a family of iron based alloys that contain a minimum of 10.5% chromium (CR). The presence of chromium creates an invisible surface film that resists oxidation and makes the material passive or corrosion resistant. There are multiple families of stainless steel which are designed for various applications and uses. Stainless grades can be further modified to meet various processing, corrosion, temperature and strength conditions.

Taking 304 and 304L stainless steel plates as an example, they are part of the austenitic family of stainless steel and they are one of the most versatile and widely used varieties of stainless plate. They are a relatively low cost stainless product and used in a variety of applications. 304 grades have excellent low temperature properties and respond well to hardening by cold working. 304 grades have good welding characteristics and post weld annealing is not normally required to restore performance. 304 SS has excellent corrosion resistance in a variety of different media. Typical specifications for 304 and 304L are ASTM A-240, ASME SA -240 and A666.

- Uniform quality

An integrated quality system from steel making through the final process ensure uniform quality in products with excellent formability and corrosion resistance.

- Attractive Finishes

To produce attractive stainless steel finishes are kept in optimum condition at all times, while automated control equipment is used to guarantee high dimensional accuracy. The supreme quality and beautiful gloss of ANSON 304L has won wide customer acclaim.

- Products for Every Application

ANSON offers a wide range of stainless steel types. ANSON has the ability to combine most stainless steel manufactures in China. If you have any specific requirement, come to us and fine better solutions.

- Excellent Corrosion Resistance

In particular, the atmospheric corrosion resistance is noticeable and the welded area is good.

- Price Competitiveness and Stability

Without the addition of nickel, the price of stainless plate is cheaper, even when the price of raw materials of nickel and molybdenum soars.

- Good Formability

Equal or better formability, compared with other conditional stainless steel.

- Excellent Physical Properties

ANSON stainless steel possesses higher thermal conductivity, smaller thermal expansion coefficient, less material weight for same size than other suppliers.

- Heat Resistance

304 has good resistance to oxidation in intermittent service up to 870°C and in continuous service to 925°C. However, continuous use at 425-860°C is not recommended if corrosion resistance in water is required. In this instance 304L is recommended due to its resistance to carbide precipitation.

Where high strength in required at temperatures above 500°C and up to 800°C, grade 304H is recommended. This material will retain aqueous corrosion resistance.

- Fabrication

Fabrication of all stainless steels should be done only with tools dedicated to stainless steel materials. Tooling and work surfaces must be thoroughly cleaned before use. These precautions are necessary to avoid cross contamination of stainless steel by easily corroded metals that may discolor the surface of the fabricated products.

- Cold Working

304 stainless steel readily work hardens. Fabrication methods involving cold working may require an intermediate annealing stage to alleviate work hardening and avoid tearing or cracking. At the completion of fabrication a full annealing operation should be employed to reduce internal stresses and optimize corrosion resistance.

- Hot Working

Fabrication methods, like forging, that involve hot working should ovvur after uniform heating to 1149-1260°C. The fabricated components should then be rapidly cooled to ensure maximum corrosion resistance.

- Heat Treatment

304 stainless steel cannot be hardened by heat treatment. Solution treatment or annealing can be done by rapid cooling after heating to 1010-1120°C.

- NM400 steel plate

- low alloy steel plate

- Cor-Ten steel plate

- stainless steel plate

- pipeline steel plate

- pressure vessel steel plate

- abrasion resistant steel plate

- shipbuilding steel plate

- steel coil

- carbon steel plate

- Cold rolled steel coil

- testing

- quality policy Steel Grades

- EN 10130 cold rolled steel coil specification

- GB/T5213 - 2008 cold rolled coil

- JIS G3141 steel coil specification

- NM500 wear resistant steel

- NM450 wear resistant steel